NAKAGAWA KNIVES

Master Blacksmith Satoshi Nakagawa (Sakai, Osaka)

Introduction:

Satoshi Nakagawa, a master blacksmith from Sakai, Osaka, trained under Kenichi Shiraki before becoming an independent craftsman. He inherited traditional techniques and his mentor’s workshop, establishing himself as a leading figure in the industry.

In Sakai, knife production is divided into specialized processes, with experts in each field collaborating to create high-quality knives. Nakagawa excels in the forging process, producing a wide variety of top-tier knives with exceptional precision and speed.

Nakagawa’s creations, such as Montanren, Enmon Suminagashi, and Genbu Suminagashi, showcase his dedication to blending traditional craftsmanship with unique, modern designs. His knives feature intricate patterns and exceptional quality, achieved through meticulous temperature control and innovative forging techniques.

Signature Works

Montanren

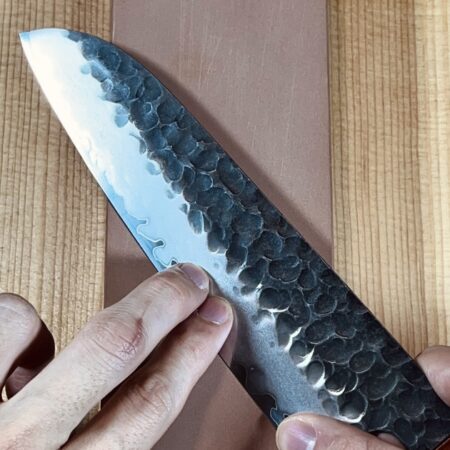

Japanese traditional knives, known as awase-wabocho, means 2 layers blade, feature a distinct boundary called “jizakai”, marking the separation between the soft iron and the steel edge.

Typically, this boundary is straight, but Satoshi Nakagawa employs a unique technique to create a beautiful wavy pattern along the edge.

He meticulously manages the temperature during forging and ensures precise, quick welding to prevent defects. This attention to detail results in knives that are not only of superior quality but also visually stunning.

Each knife is crafted with great care, reflecting Nakagawa’s dedication to excellence.

Enmon Suminagashi

Satoshi Nakagawa’s original design features unique patterns, such as the flame-like motifs in his Suminagashi knives.

These designs are the only ones of their kind in the world. Nakagawa shapes the steel sheet to achieve a balanced and visually appealing finish, ensuring that the blade’s forging process prevents defects. He meticulously grinds each steel sheet, focusing on the details, though the specific techniques are proprietary. The balance and beauty of the “jizakai” can be seen on the knife’s surface, showcasing Nakagawa’s dedication to craftsmanship. When purchasing a knife, be sure to examine the back for the intricate details.

Genbu Suminagashi

Satoshi Nakagawa’s unique pattern designs are one-of-a-kind in the world. Among these, the diamond-shaped pattern is particularly notable.

The Suminagashi design involves processing layered soft iron to create original patterns. Creating these Damascus-like patterns requires numerous prototypes, making the process highly labor-intensive.

The combination of layered steel and edge metal allows for different designs on the front and back of the knife, offering various pattern possibilities. Nakagawa’s intricate designs captivate audiences globally, resulting in more orders than he can fulfill.

Water Honyaki

The wave pattern seen near the spine of the blade is called “hamon,” and it appears only on honyaki knives. Creating high-quality water-harden honyaki knives is extremely challenging, with only a handful of craftsmen in Japan capable of producing them.

The heat treatment process requires precise temperature control, allowing only about a dozen knives to be made per day. These knives are rare and often priced above hundreds of thousands of yen. For chefs, owning a honyaki knife is a mark of mastery and remains highly sought after.

Conclusion

Satoshi Nakagawa is a pivotal figure in the knife-making industry, continuously pushing the boundaries of craftsmanship. His knives are highly sought after both in Japan and internationally, reflecting his commitment to quality and innovation. For more information and to explore his works, visit his Instagram.